Vesna Zaccheo

Auditing Makerspaces on Campus

June 17, 2019

Makerspaces in higher education are places where students can explore and become innovators in their dorm room, classroom, at a portable cart, machine shop, or almost anywhere on campus. The values underlying such spaces–creativity, collaboration, and community–are helping to fuel their rapid growth and popularity. Makers on campus regularly create jewelry, code apps, and prototypes. In the future, they will leverage technologies such as 3D printers for multi-material printing with plastics, metals, and maybe even biologics.

The emergence of makerspaces on college campuses create several questions for internal auditors.

The emergence of makerspaces on college campuses create several questions for internal auditors:

- How are these spaces governed?

- What are the roles and responsibilities of faculty, academic departments, the Environmental Health and Safety (EHS) office, the facilities department, the controller’s office, and many other units within each college and university?

- How can the organization support the culture of making in a safe, ethical and responsible environment?

Massachusetts Institute of Technology’s (MIT) Makerspace Environment

MIT has over 130,000 square feet of design and build spaces with over 300 different kinds of maker equipment. These defined spaces can be:

- Machine Shops that provide highly skilled resources to help with fabrication

- Project Spaces where students can get support for items they need to make as part of a class or research they are doing; and

- Community Spaces where members of the community gather to make and learn together.

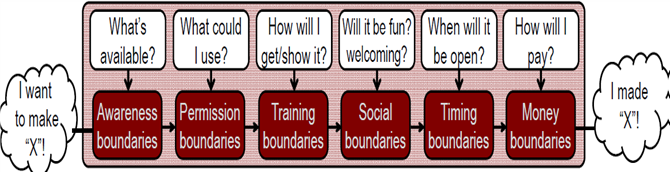

Many spaces are hybrids; they may have a primary element of one type of space but often have also characteristics of another. Within a makerspace, students primarily perform the work, which separates it from traditional campus workshops staffed to support organization goals. Students at MIT are makers, they are creative and entrepreneurial, but they often face barriers in finding and using the resources available when they want to make something.

The MIT Makersystem is a network of individuals and spaces that work together towards a common goal to share information, offer training, and provide specialized capabilities to students. Through the Makersystem network, makerspace students (or other makers) can identify spaces tailored for the arts, class projects, work with materials (e.g., metals, wood, or glass), micro/nano making, etc. Rather than remaining in an informal network, significant effort has been made to integrate making on campus and offer students access to the best space they require to safely make items needed for a class or a personal use.

While traditional areas, such as EHS, provide support by offering guidelines, training, inspection, and monitoring to help ensure safe operation of the spaces, the governance of these spaces is shared between the makers and the university. With Project Manus,[1] MIT has identified a framework to lead the effort to upgrade campus makerspaces. Within the makersystem, Project Manus has been instrumental in fostering the maker population, including building the community of makers, offering training, creating new campus makerspaces, upgrading equipment, and collaborating with other universities, the industry, and alumni. Faculty support is another crucial element of any university’s makerspace governance and framework. At MIT, leading the charge is our Maker Czar, a Department of Mechanical Engineering professor, who is a champion of hands-on learning.

The Audit Planning Stage

At the start of the audit, it is important to develop a clear understanding of the environment and processes in place. It is very likely that your environment may have some similarities, but may still be vastly different from MIT’s. Consider the following elements:

- Your college’s/university’s definition of a makerspace

- Governance, policies and programs, and process owner(s)

- Roles and responsibilities of key partners in the processes with safety, compliance, financial, student administration, or other operational duties

- Diversity of shops and makerspaces, including records of shop types/classes and risk assessment of each type

- Education and training, including record keeping and documentation

- Supervising the spaces, monitoring the risks, and communication across the university

- The diversity and variety of users (e.g., students, employees, contractors, minors)

- Access controls (physical or logical)

- Safety reviews

- Tool(s)/equipment purchasing and maintenance

- Emergency management and response

- Reporting (on training, inspections, injuries, etc.)

- System(s) used

The objective of our audit was to review the design, implementation, and operating effectiveness of control activities in place to mitigate operational, safety, and financial risks related to the administration of maker spaces. Accordingly, the scope covered an understanding of the following activities within the administration of maker spaces:

- Governance, policies and procedures

- Safety compliance, including inventory and material management

- Financial operations

As you investigate governance over the process with the various constituencies, be sure to review the available policies and procedures for existence and latest updates. Is there one repository and inventory of all maker spaces? Does your school have an oversight body in the form of a makerspace committee? What is the communication structure with each space?

Safe use of tools within makerspaces is certainly a top priority. Elements to consider when assessing the safety should be:

- College/University and local (i.e., individual space) training requirements for space users including training completion tracking

- College/University and local training requirements for makerspace supervisors

- Regular inspections of the spaces and follow-up on issues noted

- Inventory records, as well as regular inspections and repair of the tools

- Communication between the governance structures and local makerspace supervisors

- Physical access control

- Incident reporting and communicating lessons learned from actual incidents or near-misses

Within the financial operations, it is important to assess the adequacy of procurement methods when purchasing the tools, including meeting nationally recognized design and standards. Funding, including charges for services, should be reviewed for adequacy.

Testing

Each makerspace is unique. To understand the risks and the controls in place to ensure spaces are used in a safe manner, consider visiting multiple locations.

Each makerspace is unique. To understand the risks and the controls in place to ensure spaces are used in a safe manner, consider visiting multiple locations. The selection of the makerspaces visited should be a variety of shops: electronics, software, 3D printing and rapid fabrication, web design, hardware and machining, art, culinary arts, woodworking, cinematography, metalwork, jewelry, sculpting and glass blowing, paper crafts, architecture, and others as needed. A questionnaire may assist with the information gathering and assessment. Design questions around the key topics including understanding: space and usage, access to the facility, responsibilities of supervisors and users, training, safety procedures, inspections of the space and the tools, incident reports, information technology systems, and communication. Consider asking the following:

- Usage. How is the space used? How do people usually interact in the space? Assess the space layout and ask for internal guidelines, if any.

- Access. What are the access requirements and how are they enforced? Does the space log actual usage? What is the shop's policy on working alone?

- Roles. Is there a defined role for a facility supervisor, manager or equivalent? If a student has the role of a facility supervisor, how is frequent turnover (they eventually graduate) addressed?

- Safety. Ask how the dress code and use of Personal Protective Equipment is reinforced? Are machine guards present on tools that require guarding? What tools, if any, require special permission or training to use? Discuss emergency preparedness and how are evacuation procedures communicated?

- Supervisors. What are the training requirements for makerspace supervisors? How does the university track completion across the network?

- Users. What are the training requirements for space users/mentors/volunteers, both at the general and specialized level? How often is the training conducted and by whom? How is participation tracked?

- Maintenance. How is the machine/equipment maintenance performed and tracked? Is there a regular EHS and/or other inspection performed? If so, how often?

- Incidents. How many incidents have been reported? What kind? How are incidents, or near-misses, documented and shared as an opportunity for “lessons learned”?

- Data. What kind of information is collected? What are the methods to manage or protect data? What are the tools used to pay for usage (e.g., cash, checks, credit cards)? Who can purchase equipment and tools? Is there any approval process in place to ensure safety standards are maintained for new equipment purchases?

- Community. Discuss collaboration and communication steps. Are there any open house times for the community to visit the makerspaces? Any workshops or outreach activities?

Finalize the discussion by asking the makerspace representatives to name the top three ways to keep the maker space safe. Close the interview by asking them to provide any other input they may have.

Testing procedures should include, at minimum, a review of training records for both the users and the space supervisors. Inspection schedules and results should be also evaluated, as well as the procedures to follow-up on any findings from the inspections. Incident reports should be requested and reviewed. If available, access and use logs should be reviewed and cross-referenced to training logs.

Opportunities for Growth and Improvement

Depending on your specific circumstances, your tests may focus on management’s operational practices and guidelines for safety, training, staffing, and oversight to integrate the rapidly expanding concept of makerspaces into higher education culture. It is important for auditors to determine the best way to learn about new spaces during the design phase, which is essential to ensure up-to-date inventory. Having an up-to-date listing of makerspaces and engaging stakeholders in order to bolster coordination and communication will be essential to the long-term success of this exciting area.

Policies should be developed and revised as needed, including roles and responsibilities of units as they relate to makerspace. Best practices regarding the management of the spaces should be shared and adapted. Within the policies and guidance on makerspaces, inspections should be defined and well communicated. To ensure timely performance of inspections, a process should be implemented to review and monitor inspections completions after each inspection cycle.

Development of a training policy for makerspace supervisors, especially for student-run shops, is instrumental in a well-developed framework. Training for users should be offered in a variety of forms and training records should be accurate and accessible to monitor compliance. Minimum training requirements must be established for anyone who will access a makerspace, including those that do not intend to use any tools. Control banding (i.e., highly visible badges showing an individual’s abilities) or a similar practice may be used to ensure users are trained to work in a particular space and in a manner that will prevent physical injuries. With the right training and space administering processes in place, makerspaces, including those that are student-run, can provide a truly safe and reachable learning community for makers.

As students are primary users of these spaces, a safe environment is the main focus of colleges and universities. To fully support and embrace the continuous growth of the vibrant community of makers, universities can:

- Generate incident reports and ensure that incident follow-up is completed and communicated so that lessons learned are widely available

- Make the effort to reach-out to all shops to confirm that they are aware of their Emergency Preparedness Plans

- Consider establishing a makerspace advisory committee, consisting of representatives from various units, as well as students.

Continuously promoting a culture of safety is essential to provide students with an environment where they can build securely and successfully.

[1] MIT's motto, mens et manus, translates from Latin to “mind and hand.” This motto reflects the educational ideals of MIT's founders who were promoting, above all, education for practical application. Project Manus takes its name directly from this ethos.

About the Authors

/Headshot_Michael-Bowers.jpg.aspx?lang=en-US&width=125&height=180&ext=.jpg)

Michael Bowers

Michael C. Bowers, CPA, CIA, CGMA is an Associate Audit Director of Information Technology and Campus Audit Services at MIT. He joined the Audit Division in 1996 with experience in public accounting. He holds a Bachelor of Science in...

Read Full Author Bio

/Headshot_Michael-Bowers.jpg.aspx?lang=en-US&width=125&height=180&ext=.jpg)

Michael Bowers

Michael C. Bowers, CPA, CIA, CGMA is an Associate Audit Director of Information Technology and Campus Audit Services at MIT. He joined the Audit Division in 1996 with experience in public accounting. He holds a Bachelor of Science in Business Administration with a dual concentration in International Business and Accounting, and a Political Science minor, from Northeastern University. He also holds a Master of Business Administration (MBA) with a concentration in Public and Non-Profit Management from Boston University. Mike maintains his license as a Certified Public Accountant (CPA) within the Commonwealth of Massachusetts and holds designations as a Certified Internal Auditor (CIA) and a Chartered Global Management Accountant (CGMA). Mike can be reached at mbowers@mit.edu.

Articles

Auditing Makerspaces on Campus

Vesna Zaccheo

Vesna N. Zaccheo is Audit Manager within the Campus Audit Services at the Massachusetts Institute of Technology. She joined the Audit Division in 2000 with five years of internal audit experience at Data General and ten years of overall...

Read Full Author Bio

Vesna Zaccheo

Vesna N. Zaccheo is Audit Manager within the Campus Audit Services at the Massachusetts Institute of Technology. She joined the Audit Division in 2000 with five years of internal audit experience at Data General and ten years of overall professional experience. She holds a Bachelor of Science in Economics from the University Center of Economics Sciences, North Macedonia and a Master of Business Administration (MBA) with a concentration in Finance from Northeastern University. Vesna can be reached at

vnz@mit.edu.

Articles

Auditing Makerspaces on Campus